WARICUT special series

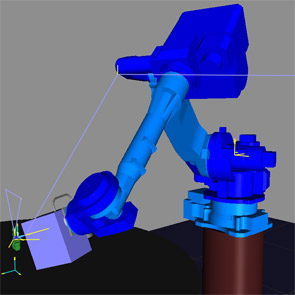

The WARICUT® technology also contains complex machining centres. In the following example, we present our robot-supported, rotary high pressure cleaning system – model HWR/1–3D.

Dimensions

Lenght: approx. 5500 mm | Width: approx. 2900 mm | Height: approx. 3200 mm

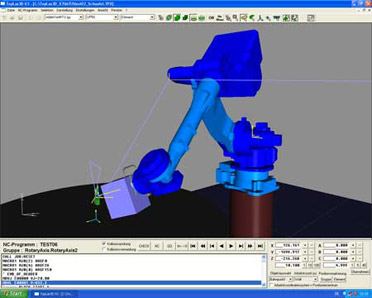

3D robot programming system

- First-class machining results due to comprehensive, user-oriented CAD/CAM functions

- Timesaving and productive work due to complete integration of the process chain from CAD to NC programming to simulation taking account of collisions

- Smooth work process due to powerful CAD interfaces

- User friendly system due to intuitive arrangement of the functionalities

Description

The casing of the robot-supported cleaning system is based on a torsion-resistant stainless steel construction with soundproofing insulation (~75 dB/A) and is divided into two areas:

Cleaning area

Here, workpieces are clamped on a CNC controlled pivoted rotary table and then cleaned using industrial robots.

The rotational cleaning head is fitted with up to 10 water nozzles which are supplied by two high pressure pumps, each with 75 kW and a complete delivery rate of 15.2 l / min at a pressure of 3,800 bar.

Service area

The silt clearance system and the dehumidification system are integrated in this area.

System components

- Casing in stainless steel construction

- Industrial robots

- CNC rotary table

- Rotational cleaning head

- Standard cleaning head

- Integrated crane system

- High pressure pumps

- Water cleaning system

- Dehumidification system