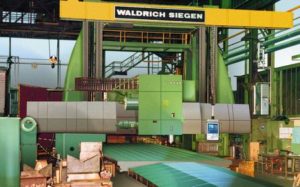

Overhaul of machine tools

Automatically more power with retrofit

Why dispose of proven machines and production equipment in an expensive and environmentally friendly way? Why interrupt proven production processes and risk competitive advantages?

Retrofitting is the answer in favor of increased productivity, time savings and retention of existing systems and machines.

The automation concepts of H.G. Ridder Automatisierungs-GmbH ensure proven production processes and competitive advantages.

H.G. Ridder GmbH is a well-known name in the field of machine tool overhaul. Since 1980, a large number of so-called retrofit projects have been carried out in Germany and worldwide. The machines to be overhauled are brought up to the latest state of the art either on site or in our factory. This includes not only the mechanical overhaul, but usually a complete conversion of the machines from conventional to state-of-the-art control technology.

We would be pleased to make you an offer for the overhaul of your machine tool, just contact us.

In close cooperation with machine and system manufacturers, H.G. Ridder Automatisierungs-GmbH designs and implements solutions that last for generations, freely in accordance with the traditional motto “Made in Germany”.

“Retrofit” saves you high costs for new machines and production facilities!