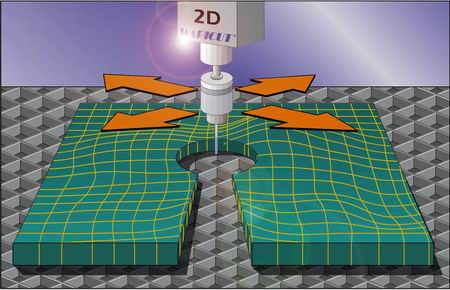

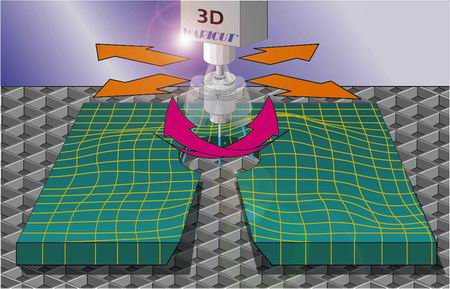

WARICUT methods

WARICUT® is the trademark of the world wide proven cutting and separating technology in the area of water jet cutting systems.

Almost all materials with different thicknesses can be machined without heating or deformation and low burr formation with this environmentally sound, cold and highly precise process.

The high pressure water jet cutting process is the alternative to thermal cutting technology. It can be used with a pressure of up to 6,000 bar.

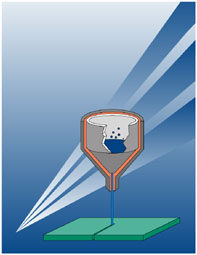

Pure water cutting technology

With pure water cutting technology, the core jet of pure water cuts the workpiece.

The pure water cutting method is used for soft to tough materials. Machines with several cutting heads are mainly used here. These can be mounted on one or several traverses. The number of cutting heads is designed according to customer requirement

| Materials | 4000 bar |

|---|---|

| Plastics | unknown |

| Foil | unknown |

| Foodstuffs | unknown |

| Rubber | up to 80 mm |

| Textiles | up to 30 mm |

| Leather | up to 30 mm |

| Wood | up to 35 mm |

| Laminates | up to 35 mm |

| Foam | up to 200 mm |

| Cardboard / paper | up to 60 mm |

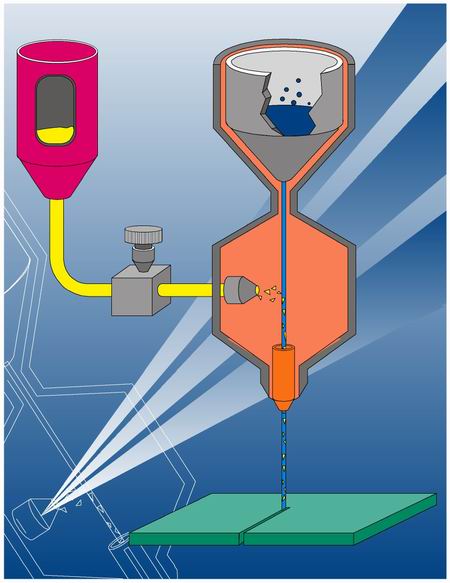

Abrasive cutting technology

In order to create an abrasive water jet from the jet of pure water, an abrasive material must be supplied to the water jet in a mixing chamber in the cutting head. Due to the high jet speed, a vacuum is produced in the cutting head using which the abrasive material is drawn into the mixing chamber and mixed with the water. The water-abrasive mixture is then focused and accelerated through an abrasive nozzle. With this abrasive water jet, the most diverse materials can now be machined.

The change from the abrasive cutting head to the pure water cutting head only takes approx. 60 seconds, thus flexibility is ensured.

| Werkstoff | 4000 bar | 6000 bar |

|---|---|---|

| Stainless Steel | up to 180 mm | up to 300 mm |

| Steel | up to 180 mm | up to 300 mm |

| Hastelloy | up to 180 mm | unknown |

| Hardox | up to 180 mm | unknown |

| Titanium | up to 250 mm | up to 350 mm |

| Aluminium | up to 300 mm | up to 400 mm |

| Non-ferrous metals | up to 180 mm | up to 300 mm |

| Plastics | up to 180 mm | unknown |

| Natural stone | up to 180 mm | unknown |

| Tiles / ceramics | up to 150 mm | unknown |

| Glass | up to 160 mm | unknown |

| Acrylic glass | up to 180 mm | unknown |

| Composite materials | up to 200 mm | unknown |

| Textiles | up to 250 mm | unknown |

| Leather | up to 250 mm | unknown |

| Wood | up to 300 mm | unknown |

| Laminates | up to 300 mm | unknown |

| Foam | up to 300 mm | unknown |

| Cardboard / paper | unknown | unknown |

The combination of pure water / abrasive cutting is used in many areas, particularly for piecework cutting.

The combination of pure water / abrasive cutting is used in many areas, particularly for piecework cutting.

The variant shown has 2 traverses, each with 2 cutting heads. One abrasive cutting head and one pure water cutting head are mounted on each of these traverses.